1. Txais txoj hauj lwm

Phau ntawv ua hauj lwm rau molded yas seem feem ntau yog npaj los ntawm ib feem designer, thiab nws cov ntsiab lus yog raws li nram no:

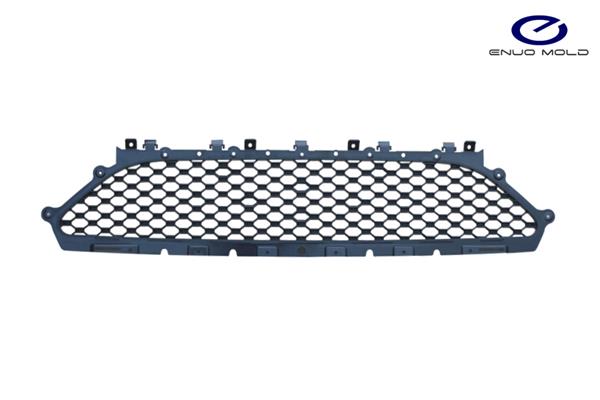

1) Cov duab kos pom zoo ntawm cov khoom siv, thiab qhia cov qib thiab pob tshab ntawm cov yas.

2) Cov lus qhia lossis kev xav tau rau cov khoom yas.

3) Cov khoom tsim tawm.

4) Cov qauv ntawm cov khoom yas.

Feem ntau cov pwm tsim cov ntawv ua hauj lwm yog npaj los ntawm cov yas seem craftsman raws li cov ntaub ntawv ua hauj lwm ntawm molded yas ib feem, thiab cov pwm tsim qauv tsim pwm raws li cov ntaub ntawv ua hauj lwm ntawm cov pwm yas pwm thiab cov pwm tsim cov ntawv ua hauj lwm.

2. Sau, txheeb xyuas, thiab zom cov ntaub ntawv qub

Sau thiab teeb tsa cov qauv tsim,moldingtxheej txheem, molding khoom, mechanical processing thiab tshwj xeeb ua cov ntaub ntawv siv thaum tsim pwm.

1) Txheeb xyuas cov duab kos ntawm cov khoom yas, nkag siab lub hom phiaj ntawm cov khoom, txheeb xyuas cov kev xav tau ntawm cov khoom yas, xws li kev tsim khoom thiab qhov raug.Piv txwv li, dab tsi yog qhov yuav tsum tau rau cov khoom yas nyob rau hauv cov nqe lus ntawm cov tsos, xim transparency, thiab kev ua tau zoo, seb lub geometric qauv, txoj kab nqes, thiab inserts ntawm cov yas qhov chaw yog tsim nyog, qhov tso cai degree ntawm molding tsis xws luag xws li weld marks thiab shrinkage qhov. , thiab seb lawv yog coated los yog tsis.Tom qab ua tiav xws li kev sib dhos, electroplating, sib txuas, thiab drilling.Xaiv qhov loj me nrog qhov siab tshaj plaws qhov tseeb ntawm cov yas rau kev tsom xam, thiab saib seb qhov kev kwv yees molding kam rau siab yog qis dua li ntawm cov yas, thiab seb cov yas uas ua tau raws li qhov yuav tsum tau ua tuaj yeem molded.Tsis tas li ntawd, nws yog ib qho tsim nyog yuav tsum nkag siab txog cov txheej txheem plasticization thiab molding txheej txheem ntawm cov yas.

2) Txheeb xyuas cov txheej txheem cov ntaub ntawv, txheeb xyuas seb cov txheej txheem molding, cov qauv khoom siv, cov khoom siv tshwj xeeb, cov qauv pwm thiab lwm yam uas yuav tsum tau muaj nyob rau hauv phau ntawv ua haujlwm yog tsim nyog thiab seb lawv puas tuaj yeem siv tau.

Cov khoom siv molding yuav tsum ua kom tau raws li qhov yuav tsum tau muaj zog ntawm cov khoom yas, thiab muaj qhov zoo fluidity, uniformity, isotropy, thiab thermal stability.Raws li lub hom phiaj ntawm cov khoom yas, cov khoom siv molding yuav tsum ua kom tau raws li qhov yuav tsum tau ua ntawm dyeing, hlau plating, cov khoom zoo nkauj, tsim nyog elasticity thiab plasticity, pob tshab lossis cov khoom sib txawv ntawm cov khoom, adhesiveness lossis weldability.

3) Txiav txim siab txoj kev molding

Siv cov txheej txheem ncaj qha, txoj kev ua kom siab los yog txoj kev txhaj tshuaj.

4) Xaiv cov khoom siv molding

Pwm yog tsim raws li cov khoom siv molding, yog li nws yuav tsum tau paub txog kev ua haujlwm, kev qhia tshwj xeeb, thiab cov yam ntxwv ntawm ntau yam khoom siv molding.Piv txwv li, rau lub tshuab txhaj tshuaj, cov hauv qab no yuav tsum tau nkag siab txog cov kev qhia tshwj xeeb: kev txhaj tshuaj muaj peev xwm, clamping siab, txhaj tshuaj siab, pwm installation loj, ejection ntaus ntawv thiab loj, nozzle qhov taub thiab nozzle kheej kheej vojvoog, sprue tes tsho positioning nplhaib loj, Qhov siab tshaj plaws thiab yam tsawg kawg nkaus pwm thickness, template stroke, thiab lwm yam, thov mus saib rau cov tsis muaj feem xyuam rau cov ntsiab lus.

Nws yog ib qho tsim nyog yuav tsum kwv yees qhov ntev ntawm cov pwm thiab txiav txim siab seb cov pwm tuaj yeem ntsia tau thiab siv rau ntawm lub tshuab txhaj tshuaj xaiv.

5) Cov qauv tsim tshwj xeeb

(1) Txiav txim siab hom pwm

Xws li nias pwm (qhib, semi-kaw, kaw), casting pwm, txhaj pwm, thiab lwm yam.

(2) Txiav txim siab lub ntsiab qauv ntawm cov pwm hom

Xaiv cov qauv pwm zoo tshaj plaws yog los txiav txim qhov tsim nyog cov cuab yeej molding thiab cov kab noj hniav zoo tagnrho, kom cov pwm nws tus kheej tuaj yeem ua tau raws li cov txheej txheem thev naus laus zis thiab kev lag luam ntawm cov yas hauv cov khoom siv tau zoo.Cov txheej txheem thev naus laus zis rau cov khoom yas yog los xyuas kom meej cov duab geometric, nto tiav thiab qhov tseeb qhov tseeb ntawm cov khoom yas.Kev lag luam kev lag luam ntawm kev tsim khoom yog ua kom tus nqi ntawm cov khoom yas qis, kev ua haujlwm siab, pwm tuaj yeem ua haujlwm tsis tu ncua, lub neej ua haujlwm ntev, thiab txuag kev ua haujlwm.

Post lub sij hawm: Sep-22-2021