1. Lub hom phiaj ntawm kev sim pwm?

Feem ntau ntawm cov pwm tsis zoo yog tshwm sim thaum lub sij hawm cov khoom plasticizing thiab molding txheej txheem, tab sis qee zaum muaj feem xyuam rau cov pwm tsim tsis tsim nyog, suav nrog cov kab noj hniav kom muaj nuj nqis;kev tsim ntawm lub tshuab txias / kub khiav;hom, txoj hauj lwm thiab qhov loj ntawm qhov rooj txhaj tshuaj, nrog rau cov qauv ntawm cov khoom geometry nws tus kheej.

Tsis tas li ntawd, thaum lub sij hawm qhov kev sim tiag tiag, txhawm rau ua kom tsis muaj pwm tsim, cov neeg ua haujlwm kuaj yuav teeb tsa qhov tsis raug, tab sis qhov tseeb cov ntaub ntawv ntau ntawm cov khoom lag luam xav tau los ntawm cov neeg siv khoom tsawg heev, ib zaug qhov ntsuas qhov ntsuas nrog ib qho kev sib txawv me ntsis, qhov zoo ntawm cov khoom loj tuaj yeem ua rau kom deb dhau qhov kev tso cai zam ntau, nws yuav ua rau cov txiaj ntsig tiag tiag yuav poob qis, tus nqi nce.

Lub hom phiaj ntawm kev sim pwm yog nrhiav cov txheej txheem zoo tshaj plaws thiab tsim pwm.Nyob rau hauv txoj kev no, txawm tias cov khoom siv, tshuab parameter lossis ib puag ncig muaj qee yam hloov pauv, cov pwm tseem tuaj yeem ua kom ruaj khov thiab loj ntau lawm tsis cuam tshuam.

2. Pwm sim Cov kauj ruam peb ua raws.

Txhawm rau kom paub tseeb tias qhov kev sim pwm raug raug, peb pab neeg yuav ua raws li cov kauj ruam hauv qab no.

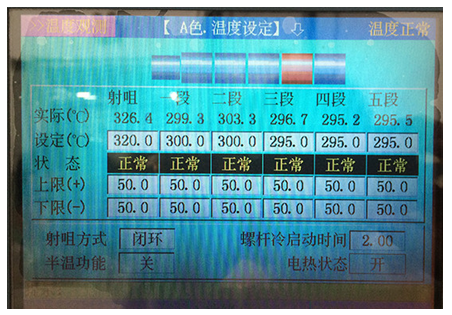

Kauj ruam 1.Teem lub tshuab txhaj tshuaj "nozzle chim" kub.

Nws yuav tsum raug sau tseg tias qhov pib qhov kub thiab txias yuav tsum yog raws li cov khoom siv tau pom zoo.Thiab tom qab ntawd raws li kev tsim khoom tshwj xeeb rau qhov tsim nyog nplua-tuning.

Tsis tas li ntawd, qhov ntsuas kub ntawm cov khoom yaj hauv lub thoob yuav tsum tau ntsuas nrog lub ntsuas ntsuas kom ua raws li qhov kev tshuaj ntsuam pom.(Peb tau muaj ob qhov xwm txheej uas ob qhov kub sib txawv mus txog 30 ℃).

Kauj Ruam 2. Teem lub pwm kub.

Ib yam li ntawd, qhov pib qhov kub thiab txias ntawm pwm yuav tsum tau ua raws li tus nqi pom zoo los ntawm cov khoom siv.Yog li ntawd, ua ntej qhov kev xeem, qhov kub ntawm cov kab noj hniav yuav tsum tau ntsuas thiab kaw.Kev ntsuas yuav tsum tau ua nyob rau ntawm qhov chaw sib txawv kom pom tias qhov kub thiab txias yog qhov sib npaug, thiab sau cov txiaj ntsig sib xws rau kev ua raws li cov pwm optimization siv.

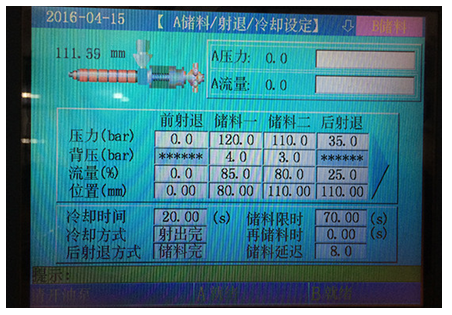

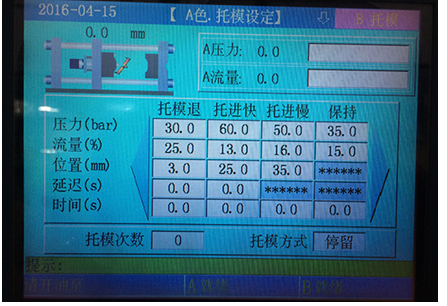

Kauj Ruam 3. Kev teeb tsa cov kev txwv.

Xws li plasticization, txhaj tshuaj siab, txhaj tshuaj ceev, lub sij hawm txias, thiab ntsia hlau ceev raws li kev paub, ces optimize nws kom tsim nyog.

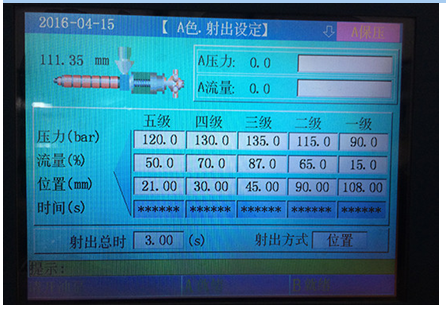

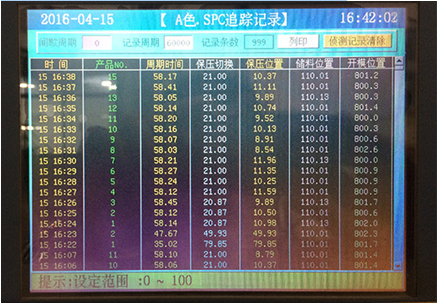

Kauj Ruam 4. Nrhiav qhov "txhaj tshuaj-tuav" qhov hloov pauv thaum lub sij hawm kev xeem.

Qhov kev hloov pauv yog qhov hloov pauv ntawm qhov kev txhaj tshuaj mus rau theem tuav lub siab, uas tuaj yeem yog txoj haujlwm txhaj tshuaj ntsia hlau, lub sijhawm sau thiab lub siab filling.Qhov no yog ib qho ntawm cov tseem ceeb tshaj plaws thiab cov yam ntxwv tseem ceeb hauv kev txhaj tshuaj molding txheej txheem.Nyob rau hauv qhov tseeb filling xeem, cov ntsiab lus hauv qab no yuav tsum tau ua raws li:

- Lub zog tuav thiab tuav lub sij hawm thaum lub sij hawm xeem feem ntau yog teem rau xoom;

- Feem ntau, cov khoom tau ntim rau 90% mus rau 98%, nyob ntawm seb qhov xwm txheej tshwj xeeb ntawm phab ntsa tuab thiab pwm qauv tsim;

- Txij li thaum qhov kev txhaj tshuaj nrawm cuam tshuam rau txoj haujlwm ntawm qhov chaw nias, nws yog ib qho tsim nyog yuav tsum rov ua kom paub meej tias qhov nias taw tes txhua zaus thaum txhaj tshuaj nrawm hloov.

Thaum lub sij hawm txhaws, peb tuaj yeem pom tias cov khoom ntim hauv pwm li cas, yog li txiav txim siab seb txoj haujlwm twg yooj yim kom muaj cua ntxiab.

Kauj Ruam 5. Nrhiav qhov txwv ntawm kev txhaj tshuaj tiag tiag.

Qhov kev txhaj tshuaj siab ntawm qhov screen yog qhov txwv ntawm qhov tseeb txhaj tshuaj, yog li nws yuav tsum tau teem ib txwm siab dua qhov tseeb.Yog tias nws qis dhau lawm thiab tom qab ntawd tau mus txog lossis dhau los ntawm qhov kev txhaj tshuaj tiag tiag, qhov kev txhaj tshuaj tiag tiag yuav cia li txo qis vim lub zog txwv, uas yuav cuam tshuam rau lub sijhawm txhaj tshuaj thiab lub voj voog molding.

Kauj ruam 6. Nrhiav qhov zoo tshaj plaws txhaj tshuaj ceev.

Qhov kev txhaj tshuaj ceev tau xa mus rau ntawm no yog qhov ceev uas lub sij hawm ua kom luv luv li sai tau thiab lub filling siab tsawg npaum li qhov ua tau.Hauv qhov txheej txheem no, cov ntsiab lus hauv qab no yuav tsum tau sau tseg:

- Feem ntau cov khoom nto tsis xws luag, tshwj xeeb tshaj yog nyob ze ntawm lub rooj vag, yog tshwm sim los ntawm kev txhaj tshuaj ceev.

- Kev txhaj tshuaj ntau theem tsuas yog siv thaum txhaj tshuaj ib zaug tsis tuaj yeem ua tau raws li qhov xav tau, tshwj xeeb tshaj yog nyob rau hauv kev sim pwm.;

- Yog tias cov pwm pwm zoo, qhov ntsuas qhov ntsuas qhov tseeb yog qhov tseeb, thiab qhov kev txhaj tshuaj nrawm txaus, muaj cov khoom lag luam flash tsis raug cuam tshuam ncaj qha rau kev txhaj tshuaj ceev.

Kauj Ruam 7. Txhim kho lub sijhawm tuav.

Lub sijhawm tuav kuj tseem hu ua lub sijhawm txhaj tshuaj.Feem ntau, lub sijhawm tuaj yeem txiav txim siab los ntawm qhov hnyav.ua rau lub sijhawm tuav sib txawv, thiab qhov zoo tshaj plaws tuav lub sij hawm yog lub sij hawm thaum pwm qhov hnyav yog maximized.

Kauj ruam 8. Optimizing lwm yam tsis.

Xws li tuav lub siab thiab clamping quab yuam.

Ua tsaug ntau rau koj lub sijhawm los nyeem ntawm no.know more about mold trial

Post lub sij hawm: Jul-25-2020