Thaum lub sij hawm kev sim pwm, molding defects feem ntau tshwm sim yam tsis muaj qhov kev kwv yees, yog li tus kws ua haujlwm pwm zoo yuav tsum muaj kev nplua nuj los txiav txim qhov laj thawj sai li sai tau, vim tias tus nqi nce ntxiv raws li lub sijhawm siv lub tshuab txhaj tshuaj.

Ntawm no peb pab neeg tau sau qee qhov kev paub dhau los, yog tias qhov kev sib qhia no tuaj yeem qhia me ntsis lus qhia kom muaj txiaj ntsig rau koj qhov kev daws teeb meem zoo sib xws, peb yuav zoo siab heev.

Ntawm no peb tham txog peb lub cim: "Burnt Marks", "Wet Marks" thiab "Air Marks".

Nta:

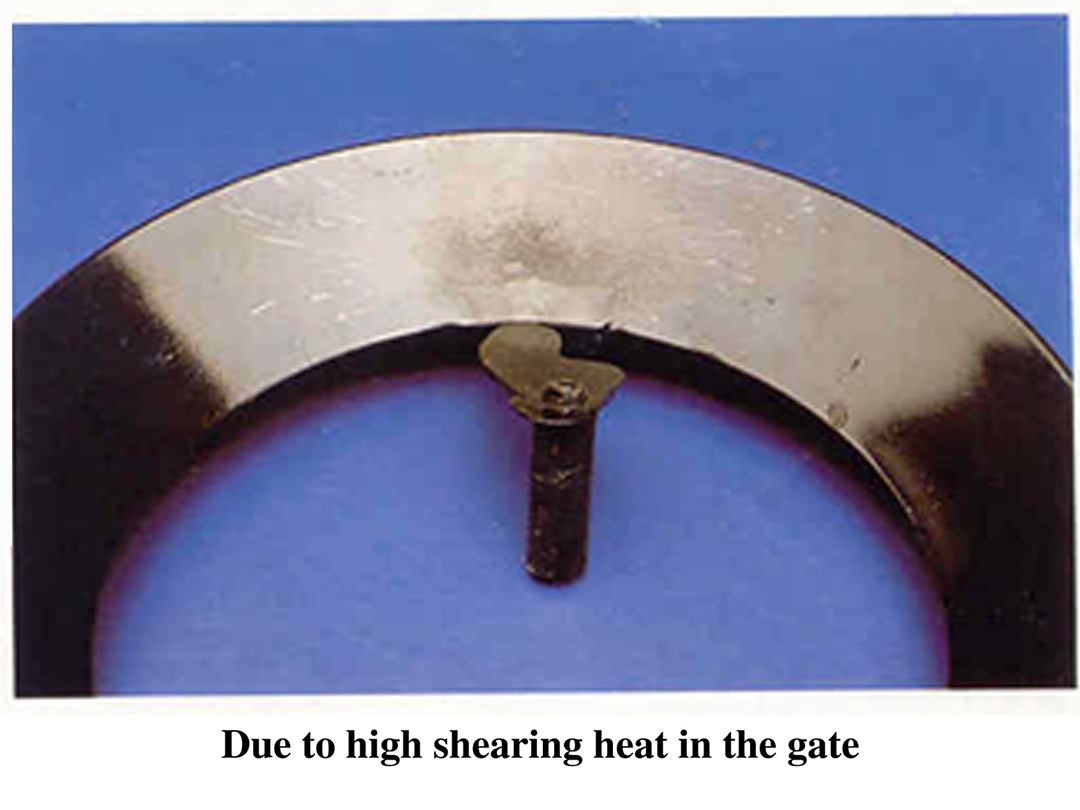

·Periodically tshwm sim

·tshwm sim nyob rau hauv qhov nqaim cross section los yog cua ntxiab txoj hauj lwm

·Lub melting kub yog yuav luag lub sab sauv txwv ntawm txhaj tshuaj kub

·Qhov tsis xws luag muaj qee yam cuam tshuam los ntawm kev txo cov xovxwm ntsia hlau ceev

·Plasticization lub sij hawm ntev dhau lawm, los yog nyob rau hauv pem hauv ntej ntawm cov xovxwm ntsia hlau ntev dhau lawm

·Cov khoom siv yas rov qab siv tau ntau dhau los yog cov khoom siv tau yaj ntau zaus ua ntej

·tshwm sim hauv pwm nrog kub khiav system

·Pwm nrog kaw nozzle (Shut Off Nozzle)

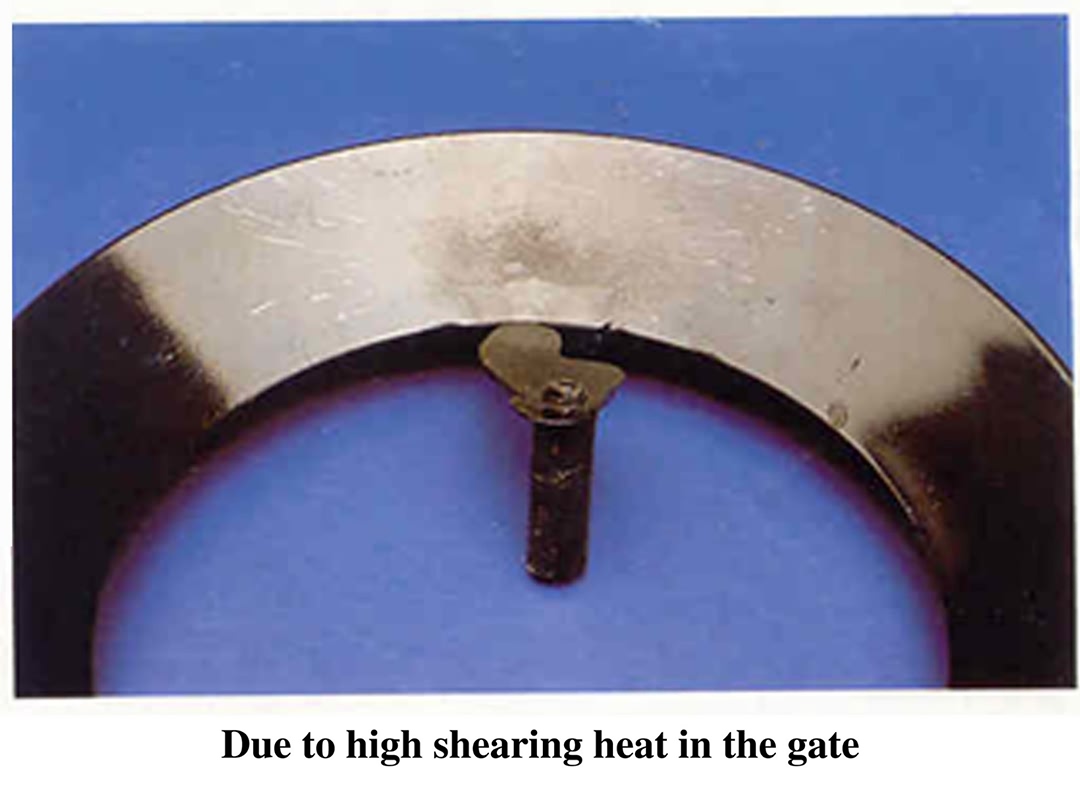

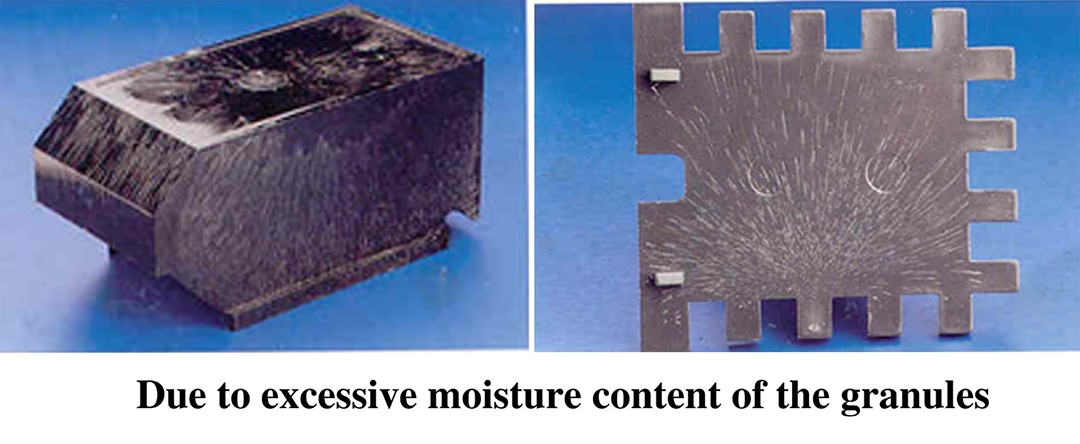

Nta:

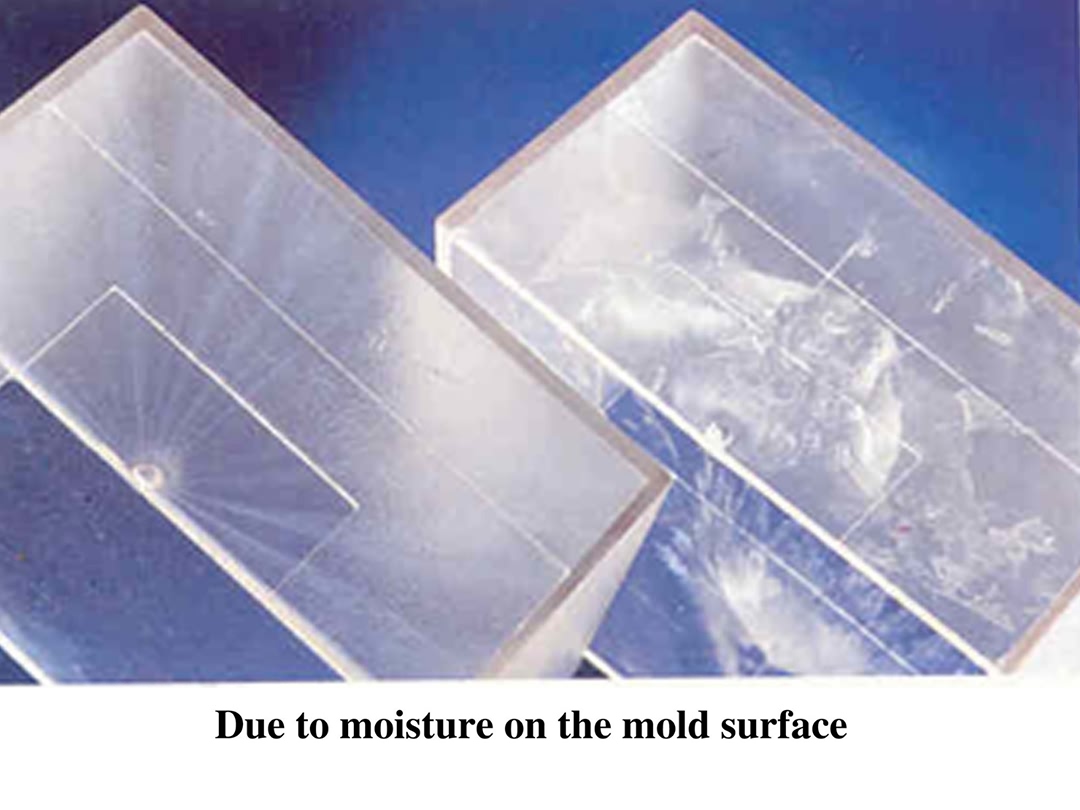

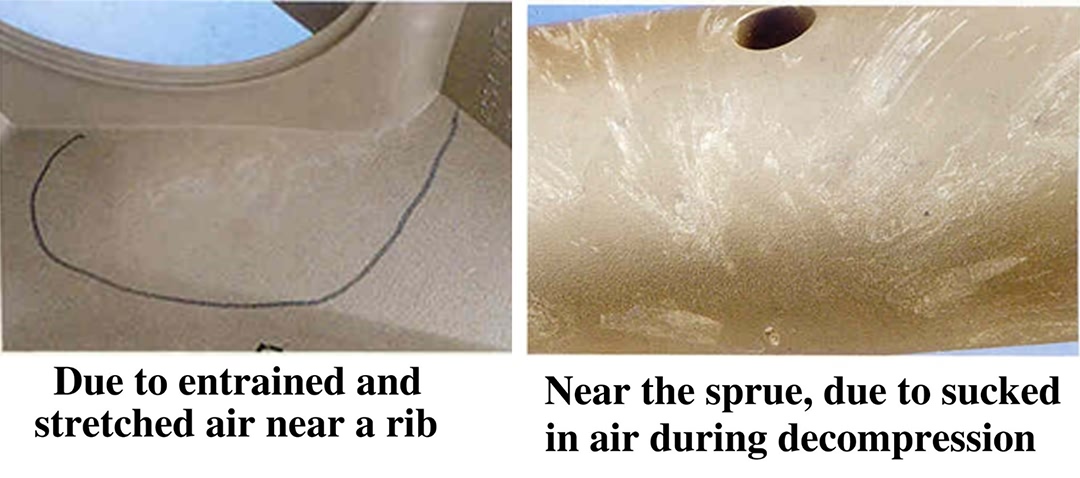

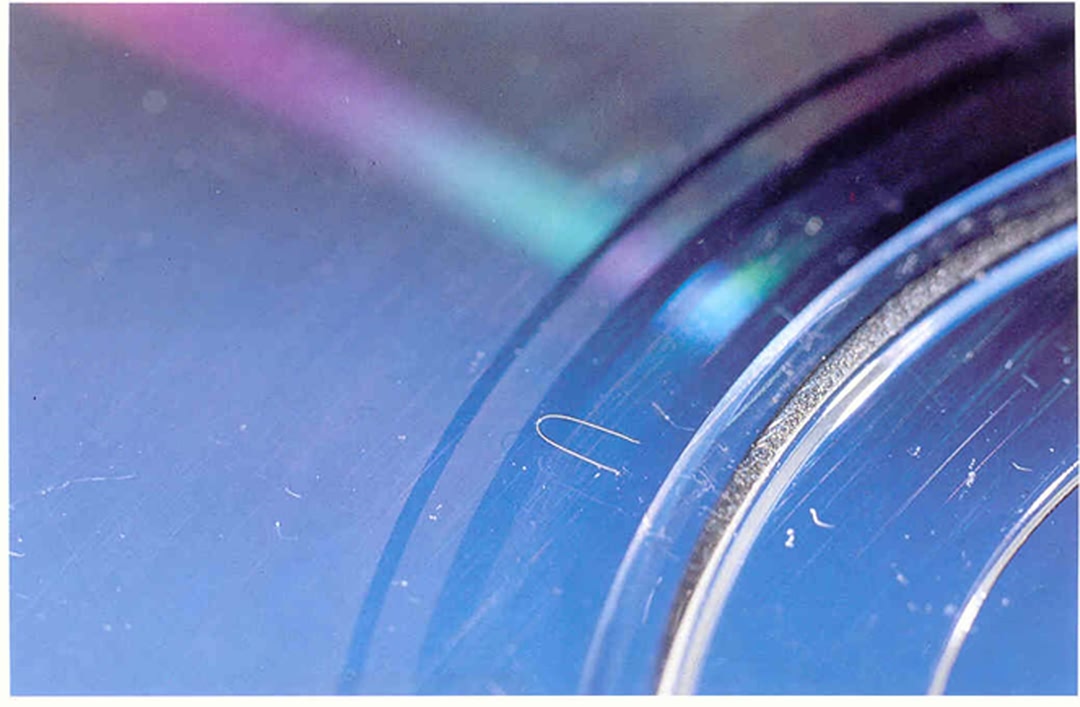

3. Air Marks

Feem ntau, cov duab ntawm cov huab cua yog ntxhib, nrog cov xim nyiaj los yog xim dawb, feem ntau tshwm sim nyob rau hauv lub kheej kheej / nkhaus nto, tav / phab ntsa thickness hloov chaw los yog nyob ib ncig ntawm nozzle, lub rooj vag nkag feem ntau zoo li nyias txheej ntawm huab cua cim; Cov cim huab cua kuj tshwm sim ntawm qhov engraving, piv txwv li: ntawv sau los yog kev nyuaj siab ntawm qhov chaw.

Tsuas yog cov hom saum toj no, peb kuj muaj "Glass-fiber marks" thiab "Color marks" on the part surface.so yav tom ntej, ntau molding defects kev paub yuav muab qhia rau cov phooj ywg nyob rau linkedin, yog tias koj muaj kev xav txawv ntawm kuv tus ncej, thov ua siab zoo qhia rau kuv paub koj cov lus, raws li peb paub, linkedin yeej ib txwm yog lub platform zoo rau peb los qhia, kawm thiab txhim kho!

Post lub sij hawm: Oct-26-2020