Cov pwm yas muaj kev sib raug zoo hauv cov txheej txheem ntawm kev tsim thiab kev tsim thiab kev ua cov yas. Kev ua tiav thiab tsis ua tiav ntawm kev ua cov yas yog nyob ntawm cov pwm tsim cov nyhuv thiab pwm tsim zoo ntawm qib loj, thiab cov pwm tsim pwm yog raws li cov khoom siv yas tsim. Raws li qhov yooj yim. Yog li cov qauv dab tsi yuav tsum tau xav txog hauv kev tsim cov pwm yas? Cia peb nkag siab ua ke:

1. Parting nto: thaum cov pwm raug kaw, cov kab noj hniav thiab cov pwm puag yog sib txuam nrog ib leeg kom kov qhov chaw. Kev xaiv ntawm nws qhov chaw thiab cov txheej txheem yog cuam tshuam los ntawm cov khoom xws li cov khoom zoo li thiab cov tsos, phab ntsa thickness, txoj kev tsim, tom qab tsim technology, pwm hom thiab qauv, pwm ejection txoj kev, thiab txoj kev tshuab qauv.

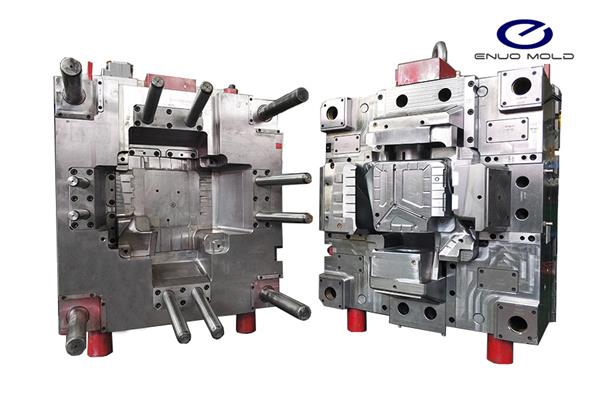

2. Cov qauv tsim: uas yog, qhia rail sliders, inclined qhia posts, ncaj saum blocks, thiab lwm yam ntawm complex pwm. Kev tsim cov qauv tsim yog ib qho tseem ceeb heev, uas muaj feem xyuam rau lub neej kev pab cuam ntawm pwm, ntau lawm thiab ua lub sij hawm, tus nqi, cov khoom zoo, thiab lwm yam. Yog li ntawd, cov qauv tseem ceeb ntawm cov pwm tsim complex yuav tsum muaj ntau dua kev muaj peev xwm rau lub designer, thiab nrhiav kev zoo tag nrho yog yooj yim dua thiab ruaj khov. Durable, ntau kev lag luam kev tsim kho kev tsim kho.

3. Pwm precision: tsis txhob jams, precise positioning, positioning pins, circlips, thiab lwm yam. Lub xov tooj ntawm tes positioning system muaj feem xyuam rau cov khoom zoo li, pwm zoo thiab kev pab cuam lub neej. Nyob ntawm tus qauv tsim pwm, cov txheej txheem sib txawv qhov tseeb raug xaiv. Tus yuam sij rau qib raug yog tswj los ntawm kev tsim khoom thiab kev ua haujlwm. Qhov tseeb qhov chaw ntawm cov tub ntxhais pwm feem ntau yog txiav txim siab los ntawm tus tsim qauv. , Tsim kom muaj txiaj ntsig zoo dua thiab yooj yim-rau-kho kom meej txoj hauv kev.

4. Pouring system: qhov kev nyab xeeb pub noj channel los ntawm lub nozzle ntawm lub tshuab yas mus rau nruab nrab ntawm cov kab noj hniav, suav nrog cov channel nrov, kev sib cais channel, cov kua nplaum inlet thiab cov khoom txias hauv kab noj hniav. Tshwj xeeb, kev xaiv ntawm qhov chaw txhaj tshuaj yuav tsum muaj txiaj ntsig zoo rau cov yas molten kom sau cov kab noj hniav nrog fluidity zoo heev. Cov khoom ntws ntws txuas nrog rau cov khoom thiab cov khoom txias ntawm qhov chaw txhaj tshuaj yog yooj yim rau eject los ntawm pwm thaum nws tawm ntawm pwm. Muab tshem tawm.

5. Yas shrinkage tus nqi thiab ntau yam uas cuam tshuam cov khoom seem raug, xws li pwm manufacturing thiab installation deviation, pwm puas, thiab lwm yam. Tsis tas li ntawd, thaum tsim cov xovxwm pwm thiab txhaj tshuaj pwm, cov txheej txheem ntawm kev tsim tshuab thiab kev sib txuam ntawm cov Lub ntsiab yam ntxwv tsis yuav tsum tau xav txog. Cov txheej txheem tsim qauv ntawm kev pabcuam tsim tau siv dav hauv kev tsim pwm yas. Tsis tas li ntawd, nyob rau hauv cov txheej txheem tsim pwm yas, cov txheej txheem pwm ntawm cov pwm yuav tsum tau txiav txim siab, kom tag nrho cov pwm tuaj yeem ua tiav cov txiaj ntsig zoo tshaj plaws, thiab cov pwm yas tuaj yeem tsim tau zoo hauv kev txhaj tshuaj pwm ua theem.

Post lub sij hawm: Oct-30-2021