1. Khoom phab ntsa thickness

(1) Txhua yam yas muaj qee yam ntawm phab ntsa tuab, feem ntau 0.5 txog 4 hli. Thaum cov phab ntsa thickness ntau tshaj 4 hli, nws yuav ua rau lub sij hawm txias yuav ntev heev thiab ua rau shrinkage thiab lwm yam teeb meem. Xav txog kev hloov cov qauv khoom.

(2) Lub thickness ntawm phab ntsa tsis sib xws yuav ua rau deg shrinkage.

(3) Cov phab ntsa tuab tsis sib xws yuav ua rau cov pores thiab vuam kab.

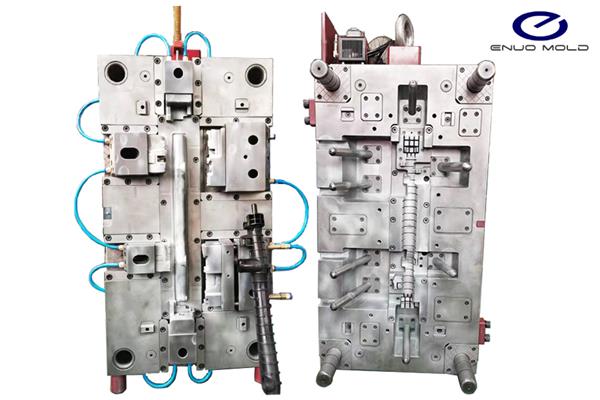

2. Pwm qhib kev taw qhia thiab kev faib kab

Thaum pib ntawm kev tsim ntawm txhua qhov kev txhaj tshuaj, cov pwm qhib cov kev taw qhia thiab cov kab sib faib yuav tsum tau txiav txim siab ua ntej kom ntseeg tau tias cov tub ntxhais rub tawm slider mechanism raug txo qis thiab qhov cuam tshuam ntawm txoj kab sib faib ntawm cov tsos raug tshem tawm.

(1) Tom qab cov pwm qhib kev taw qhia tau txiav txim siab, cov hlua txuas ntxiv, buckles, protrusions thiab lwm yam qauv ntawm cov khoom tsim los ua kom zoo raws li cov pwm qhib kev taw qhia kom ntau li ntau tau, kom tsis txhob muaj cov tub ntxhais rub thiab txo cov kab seam thiab ncua lub neej ntawm pwm.

(2) Tom qab cov pwm qhib kev taw qhia tau txiav txim siab, ib txoj kab uas tsim nyog tuaj yeem raug xaiv kom tsis txhob muaj qhov cuam tshuam hauv pwm qhib kev taw qhia, txhawm rau txhim kho qhov tsos thiab kev ua haujlwm.

3. Demoulding txoj kab nqes

(1) Tsim nyog demoulding nqes hav tuaj yeem zam cov khoom fluffing (rub). Qhov demoulding txoj kab nqes ntawm qhov chaw du yuav tsum siab dua lossis sib npaug li 0.5 degrees, qhov saum npoo ntawm cov tawv nqaij zoo (xuab zeb nto) yuav tsum siab tshaj 1 degree, thiab cov tawv nqaij tawv yuav tsum siab dua 1.5 degrees.

(2) Tsim nyog demoulding txoj kab nqes tuaj yeem zam cov khoom puas tsuaj, xws li sab saum toj dawb, sab saum toj deformation, thiab sab saum toj rupture.

(3) Thaum tsim cov khoom lag luam nrog cov qauv sib sib zog nqus, txoj kab nqes ntawm sab nrauv yuav tsum loj dua li txoj kab nqes ntawm sab hauv kom ntau li ntau tau los xyuas kom meej tias cov pwm tseem ceeb tsis sib txawv thaum txhaj tshuaj molding, tau txais cov khoom zoo sib xws. phab ntsa thickness, thiab xyuas kom meej cov khoom muaj zog ntawm cov khoom qhib.

4. Txhim kho cov tav

(1) Tsim nyog daim ntawv thov ntawm reinforcing ribs yuav ua rau kom cov khoom rigidity thiab txo deformation.

(2) Lub thickness ntawm lub stiffener yuav tsum yog ≤ (0.5 ~ 0.7) T khoom phab ntsa thickness, txwv tsis pub lub nto yuav shrinkage.

(3) Txoj kab nqes ib sab ntawm txoj hlua txuas ntxiv (Shanghai Mould Design Training School) yuav tsum siab dua 1.5 ° kom tsis txhob raug mob sab saum toj.

Post lub sij hawm: Sep-28-2022