Yas pwm yog ib qho cuab yeej uas sib txuam nrog cov tshuab yas molding hauv kev lag luam yas kom muab cov khoom yas ua tiav thiab qhov loj me. Raws li cov txheej txheem molding sib txawv, nws tuaj yeem muab faib ua ntau hom pwm.

1. High-expanded polystyrene molding tuag

Nws yog ib hom pwm uas siv cov polystyrene nthuav dav (cov khoom siv hlaws ntawm polystyrene thiab foaming tus neeg sawv cev) cov ntaub ntawv raw los ua npuas ntim cov ntaub ntawv ntawm ntau yam kev xav tau.

Lub hauv paus ntsiab lus yog qhov nthuav dav polystyrene tuaj yeem ua rau hauv pwm, suav nrog ob hom kev ua haujlwm yooj yim ntawm cov pwm thiab hydraulic ncaj nraim los ntawm cov yas pwm, uas yog siv los tsim cov khoom ntim rau cov khoom lag luam. Cov khoom siv los ua cov pwm no yog cam khwb cia txhuas, stainless hlau, bronze, thiab lwm yam.

2. Compression pwm

Xws li compression molding thiab txhaj tshuaj molding ob hom pwm pwm. Lawv yog hom pwm feem ntau siv los pwm thermosetting plastics, thiab lawv cov khoom siv sib xws yog lub tshuab xovxwm molding.

Txoj kev compression molding raws li cov yam ntxwv ntawm cov yas, cov pwm yog rhuab mus rau molding kub (feem ntau 103 ° 108 °), ces ntsuas compression molding hmoov yog muab tso rau hauv pwm kab noj hniav thiab lub chamber pub mis, pwm kaw, thiab cov yas yog rhuab nyob rau hauv high kub thiab kub siab. soften lub viscous ntws, solidify thiab zoo tom qab ib tug tej lub sij hawm ntawm lub sij hawm, thiab ua tus yam khoom zoo li.

Qhov sib txawv ntawm kev txhaj tshuaj molding thiab compression molding yog tias tsis muaj cov khoom noj sib cais. Cov pwm raug kaw ua ntej molding, thiab cov yas yog preheated nyob rau hauv lub chamber pub thiab ua ib tug viscous flow xeev. Nyob rau hauv qhov kev txiav txim siab, nws yog kho thiab nyem rau hauv pwm kab noj hniav kom tawv thiab daim ntawv.

Cov pwm compression yog tsim los ntawm cov kab noj hniav, cov kab noj hniav, kev taw qhia mechanism, ejecting qhov chaw, cua sov system, thiab lwm yam. Txhaj pwm yog dav siv nyob rau hauv ntim cov khoom siv hluav taws xob. Cov ntaub ntawv siv hauv kev tsim cov pwm compression yog tib yam li cov pwm txhaj tshuaj.

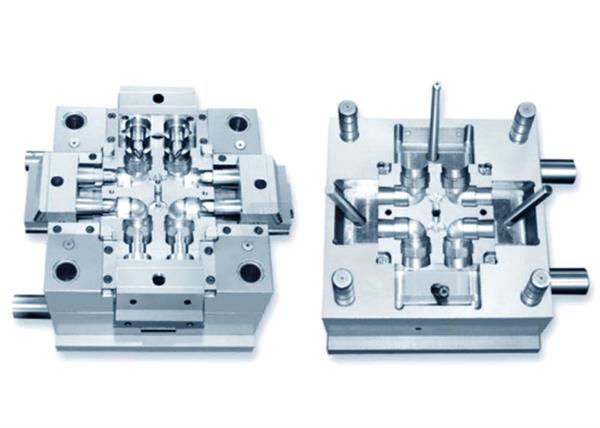

3. Txhaj pwm

Nws yog feem ntau yog cov pwm molding uas feem ntau siv hauv kev tsim cov khoom siv thermoplastic. Cov cuab yeej ua haujlwm sib raug rau kev txhaj tshuaj pwm yog lub tshuab txhaj tshuaj molding. Cov yas yog thawj zaug rhuab thiab melted nyob rau hauv lub cua kub chim nyob rau hauv qab ntawm lub tshuab txhaj tshuaj molding. Nyob rau hauv lub laub ntawm lub ntsaws, nws nkag mus rau hauv cov pwm kab noj hniav los ntawm kev txhaj tshuaj molding tshuab nozzle thiab cov txheej txheem ntawm cov pwm, thiab cov yas yog txias thiab hardened rau daim ntawv, thiab cov khoom yog tau los ntawm demolding.

Nws cov qauv feem ntau yog tsim los ntawm kev tsim cov khoom, cov txheej txheem pouring, kev taw qhia qhov chaw, lub tshuab thawb tawm, kev tswj qhov kub thiab txias, qhov tso pa tawm, cov khoom txhawb nqa thiab lwm yam, thiab nws yog ua los ntawm cov yas pwm hlau. Cov txheej txheem txhaj tshuaj molding feem ntau tsuas yog tsim nyog rau kev tsim cov khoom siv thermoplastic. Cov khoom yas tsim los ntawm kev txhaj tshuaj molding yog dav heev. Los ntawm cov khoom siv niaj hnub mus rau ntau yam khoom siv hluav taws xob thiab cov khoom siv pib, lawv txhua tus tsim nrog cov pwm txhaj tshuaj. Ib txoj hauv kev siv ntau tshaj plaws hauv kev tsim cov khoom yas.

4. Tshuab pwm

Cov pwm siv los tsim cov thawv yas hollow cov khoom (xws li lub raj mis dej haus, cov khoom siv tshuaj txhua hnub thiab lwm cov thawv ntim khoom). Daim ntawv ntawm tshuab moulding feem ntau suav nrog extrusion tshuab moulding thiab txhaj tshuaj molding raws li txoj cai txheej txheem. Lub hauv paus ntsiab lus tseem ceeb suav nrog extrusion tshuab moulding, txhaj tshuaj molding, txhaj tshuaj txuas ntxiv tshuab moulding (feem ntau hu ua kev txhaj tshuaj stretch tshuab), ntau txheej tshuab moulding, ntawv tshuab moulding, thiab lwm yam. Cov khoom siv sib txuas rau tshuab moulding ntawm cov khoom hollow feem ntau hu ua yas tshuab moulding tshuab, thiab tshuab moulding tsuas yog tsim rau kev tsim cov khoom siv thermoplastic. Cov qauv ntawm lub tshuab pwm yog qhov yooj yim, thiab cov khoom siv feem ntau yog ua los ntawm carbon.

5. Extrusion tuag

Ib hom pwm siv los tsim cov khoom yas txuas ntxiv, tseem hu ua extrusion molding taub hau, yog dav siv hauv kev ua cov kav dej, tuav, monofilaments, daim hlau, zaj duab xis, hlau thiab cable cladding, profiled cov ntaub ntawv, thiab lwm yam.

Cov khoom siv sib xyaw ua ke yog cov yas extruder. Lub hauv paus ntsiab lus yog tias cov khoom yas yog melted thiab plasticized nyob rau hauv cov kev mob ntawm cov cua sov thiab cov ntsia hlau tig ntawm lub extruder, thiab yog ua nyob rau hauv tib tug ntoo khaub lig-section raws li cov duab ntawm cov tuag los ntawm ib tug tuag ntawm ib tug tshwj xeeb zoo. Cov khoom yas tsis tu ncua. Nws cov ntaub ntawv tsim khoom feem ntau yog carbon steel qauv, cov cuab yeej alloy, thiab lwm yam, thiab qee qhov extrusion tuag kuj yog inlaid nrog hnav-resistant cov ntaub ntawv xws li pob zeb diamond ntawm cov khoom uas yuav tsum tau hnav-resistant.

Cov txheej txheem extrusion feem ntau tsuas yog tsim nyog rau kev tsim cov khoom siv thermoplastic, uas txawv txawv ntawm cov pwm txhaj tshuaj thiab compression pwm hauv cov qauv.

6. Pwm pwm

Ib lub pwm uas siv cov ntawv yas thiab cov ntawv ua cov ntaub ntawv raw los tsim qee cov khoom yas yooj yim. Nyob rau hauv cov ntaub ntawv ntawm softening, nws yog deformed thiab txuas mus rau lub kab noj hniav ntawm cov pwm kom tau cov khoom pwm xav tau, uas yog tsuas yog siv nyob rau hauv zus tau tej cov khoom siv niaj hnub, khoom noj khoom haus thiab cov khoom ua si ntim khoom.

Post lub sij hawm: Feb-12-2022