Lub Tsib Hlis 15, 2017 - pwm xa khoom

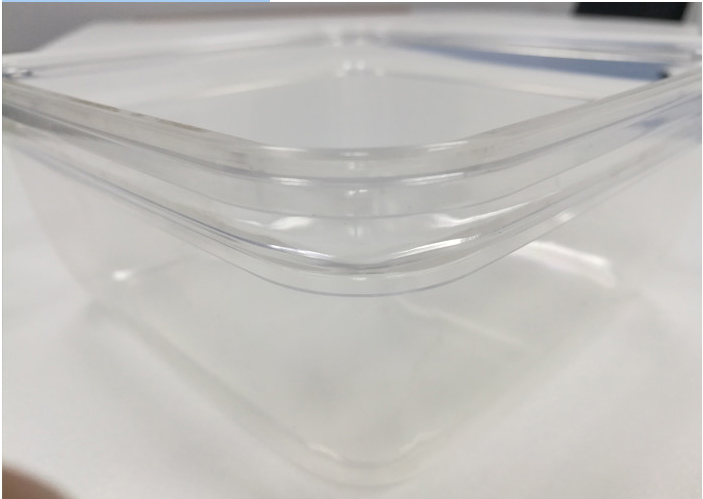

Tom qab ob peb lub hlis ua haujlwm nyuaj, ib pawg ntawm tsev neeg (khoom noj khoom haus-lub thawv) pwm raug xa mus rau cov neeg siv khoom. Raws li cov khoom yog pob tshab (raws li daim duab saum toj no qhia), thiab cov neeg siv khoom muaj kev xav tau siab ntawm cov khoom seem. Peb pab neeg ua haujlwm engineering tau ua ntau yam los kov yeej cov teeb meem cua qhov cua. Thaum kawg, peb cov neeg muas zaub tau zoo siab nrog cov pwm no, ua tsaug ntau rau koj kev txhawb nqa Kuv cov npoj yaig, koj yog kuv tus phab ej. ua tsaug rau txhua yam koj siv zog! Lol...

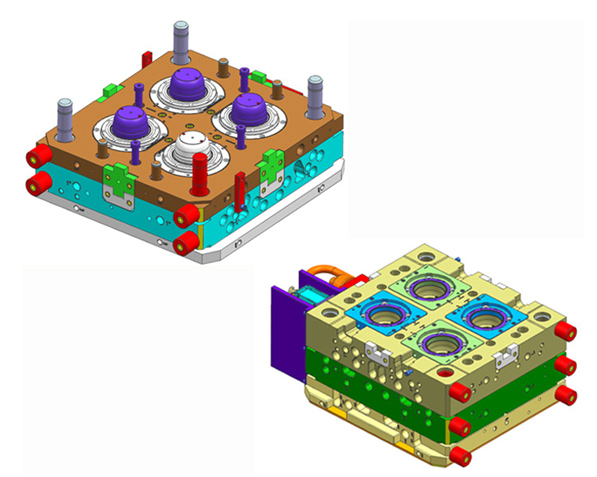

Saum toj no yog cov khoom txhaj los ntawm pwm uas peb tau ua.

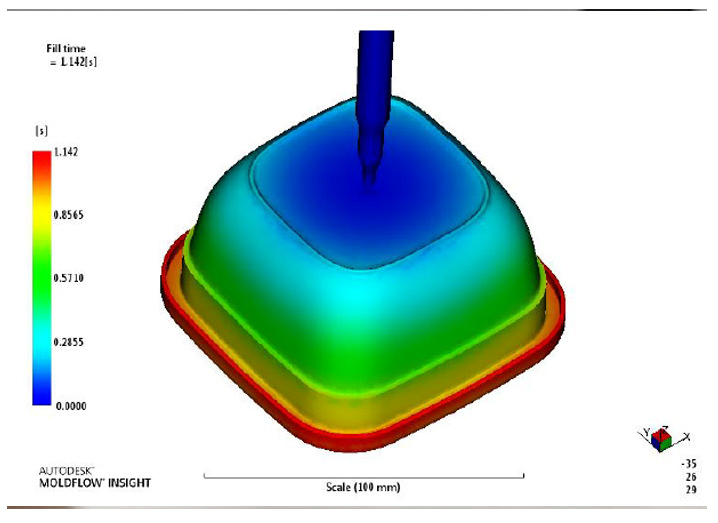

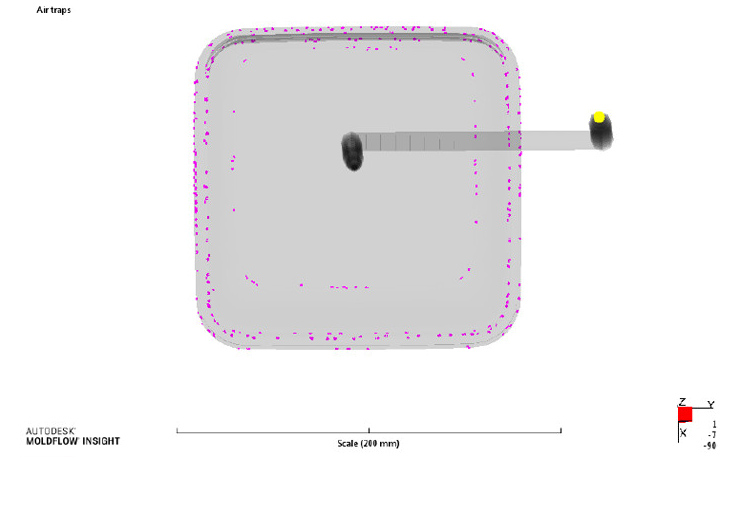

Tej zaum qee cov phooj ywg muaj kev paub txog pob tshab qhov chaw pwm tsim khoom. Raws li peb paub, cov tais no tsis yog tsuas yog cov khoom seem, tab sis kuj yog cov khoom pob tshab molded. Yog li, nws cov tsos mob yog qhov tshwj xeeb, yog li huab cua venting, luv-qee thiab ib feem ntawm qhov tsis xws luag yuav tsum tau zam. Nyob rau hauv tas li ntawd, yuav ua li cas los tsim cov inserts kom muaj ib tug zoo venting txheej xwm los ua tus yuam sij los xyuas kom meej qhov kawg pwm zoo, tau kawg teem ib tug zoo xovxwm parameter kuj yog ib qho tseem ceeb heev kev pab.

Tshwj xeeb tshaj yog muaj 3 kauj ruam geometry ntawm ib feem, yog li cov cua venting ua ib qho teeb meem loj. yuav tsum muaj kev tsim pwm paub txog qhov xwm txheej peb tau ntsib!

ok, cia peb tshuaj xyuas cov txheej txheem ua tiav ntawm pwm ua.

Kauj Ruam 1: Cov neeg siv khoom tso qhov kev txiav txim nrog cov ntaub ntawv ib feem.

Tau txais qhov "2D / 3D cov ntaub ntawv", "kev txhaj tshuaj tshuab loj" thiab "ib feem ntawm cov khoom siv" thiab lwm yam.

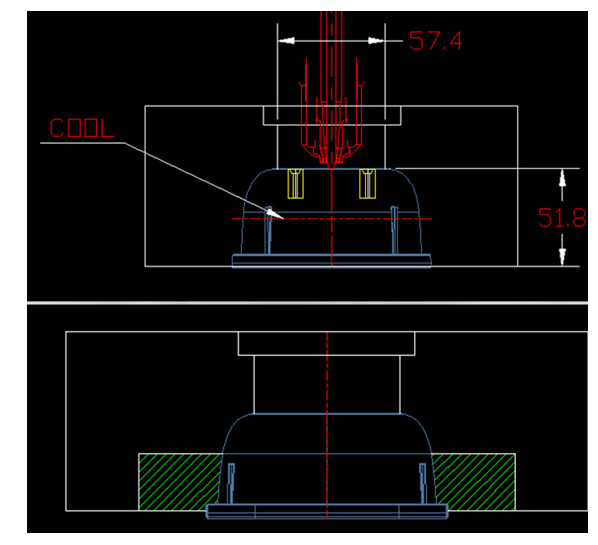

Kauj ruam 2: Mould-flow thiab DFM daim ntawv qhia

Ua cov pwm khiav tsom, raws li kev soj ntsuam tau los ua daim ntawv tshaj tawm DFM. Kev sib txuas lus nrog cov neeg siv khoom los txiav txim siab tus qauv tsim pwm.

Kauj Ruam 3: Pwm tsim Peb cov neeg tsim pwm yuav ua tiav cov qauv tsim raws li cov pwm ntws thiab DFM daim ntawv qhia. Tom qab ntawd xa tus qauv tsim rau cov neeg siv khoom kom siv tau.

Kauj Ruam 4: Pwm tsim thiab sib dhos Tom qab tau txais kev pom zoo ntawm cov neeg siv khoom txog qhov kawg pwm tsim, peb pib steel machining thiab cov khoom sib dhos.

Kauj Ruam 5: Pwm sim

Pwm sim yog cov txheej txheem tseem ceeb tshaj plaws los tshuaj xyuas cov pwm tsim kom zoo, sim ua kom tawg cov pwm teeb meem tom qab ntawd daws nws ntawm peb cov nroj tsuag, kom ntseeg tau tias cov pwm tuaj yeem tsim tau zoo ntawm cov neeg siv khoom txhaj tshuaj.

Kauj Ruam 6: Pwm optimizing.

Raws li qhov tshwm sim ntawm kev sim pwm, peb yuav ua cov pwm txhim kho kom zoo dua cov teeb meem pwm. Feem ntau peb yuav muaj pwm kuaj 1-3 zaug kom tau cov pwm kom ncav cuag cov neeg siv khoom.

Kauj Ruam 7: Kev xa khoom xa tuaj.

Tom qab tau txais kev pom zoo rau cov neeg siv khoom pwm xa tuaj, peb yuav ntim cov pwm zoo ces hu rau tus neeg xa khoom xa tuaj pwm rau cov neeg siv khoom.

Post lub sij hawm: Jul-26-2020